Lean construction recognizes that mistakes are inevitable in the implementation of schedules due to the fundamental complexity of construction activities. In other words, the full implementation of the daily and weekly schedules would rather be an exception to the general rule.

To boost the implementation of schedules, preparation of activities and levelling of civil and installation work flows shall be considered as the most important process of construction management.

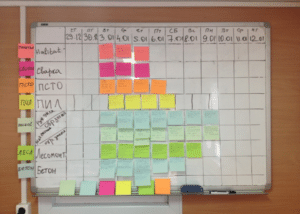

The Last Planner System guarantees high reliability of planning and execution of works, as well as creation of necessary trust in the teamwork environment. The Last Planner System means that detailed work plans are created by those who perform the work. The system reviews the plan alongside its implementation to ensure that the commitments made are linked to “milestones” and that these commitments are firm, timely and not ambiguous. The Last Planner System opens the door for the specialists engaged in work (project) management at a relevant level of detail to discuss works before the issues become critical. These discussions increase the reliability of work process flows and recognize that the relationship between performing authorities is critical to this process.

A major advantage of this system is that it is applicable to all construction projects.

Also, it is necessary to point out that LPS as a tool reveals itself not only in solving issues and current problems, its main aim is collaborative preparation of a uniform work schedule by all project participants. This requires EACH participant to study the regulatory, technical and organizational project materials beforehand. The thorough study of project details by the participants to create a uniform schedule or master schedule allows to consider all project risks, work out the most effective work sequence at the planning stage and thus load necessary resources and simulate various options of work performance in order to choose the most effective one.

A key to successful project delivery in Syrlasu Company is the development of the planning system using LPS and a dispatching method.

At the same time, it is important to understand that such principles as interaction, dialogue and training should be the key ones in construction. Collaborative development of plans and their discussion enable not only to create a realistic plan but also discuss pressing problems and find team solutions. So, the development of the planning and work schedule systems allows to pull problems while discussion of problems helps find effective solutions thus improving activities in different areas.

Thus, the production system philosophy is the foundation of lean production in construction companies while the Last Planner System is a key pulling tool, which helps detect project delivery problems and implement different tools of lean production.